|

| PRODUCTS |

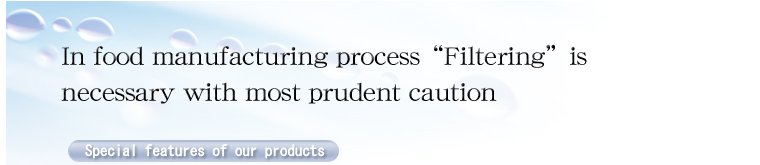

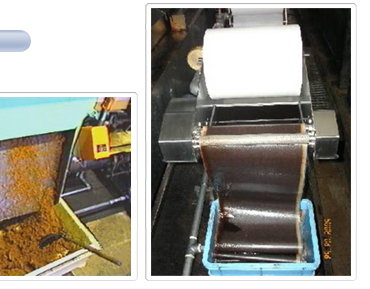

Large and medium size continuous and automatic filter NAFD type

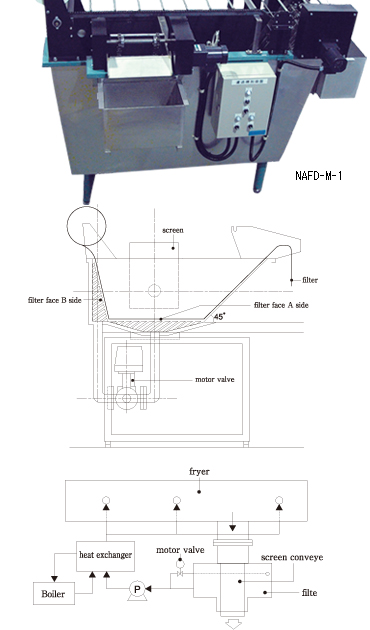

Fully Automatic continuous circulating and Filtering Equipment MM・L type |

|

|

| Fully automatic and continuous filter by automatic roll up mechanism |

We have wide variety of filtering system as shown below so that

customer can choose the most suitable filtering system for edible

oil or water or else |

|

| This method is do not use special seal or mechanical hand seal, when the liquid through the filter it's grow resistance automatically happen so seal form come into being. We realized when the filter close, the sensor catch on and roll up the filter automatically From setting roll style filter, so realize uninhabited automation of filter change works. |

●Large filtering capacity type ranging from 1,000L/min〜4,000L /min for snack foods frying

●Normal capacity type for ordinary fryer

●Others for effective filtration of other foreign particles |

|

|

Three major function make good

use of 100% frying Process |

|

1.All, perfect filtering

Two filter side filtering alternately, and all of passing oil filtering perfectly.

|

|

2.High efficient filtering

Continuous Strainer, and filter combine with each other, make efficient filtering. |

|

3.Filter roll up miss sensor make it perfectly

Filter roll up miss or some filter trouble sensor act on, and alarm sound

.

|

|

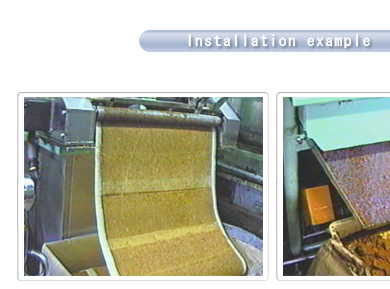

Uses |

|

・Fryer produce of foods

・And others, some food contained dregs and foreign matters with their water and Seasoning need to filtering.

|

|

Filtering process |

|

| The oil coming from fryer Lange size contamination remove to out side by screen or backet conveyor, ordinaly filtering do A side. When filter closed motor valve open,Filter move to rolle up according to filtering B side after. Fixed filter move, A side filting start again. |

|

|

|

|

|

Two major function to revolute

the image of edible oil Filtering |

|

1. Fully Automation continuous Filtering

Filtering mechanism works in fully automatic throughout frying operation. |

|

2. Prevent from Oxidation of edible oil

Prevent Oxidation to remove contaminations into the edible oil. |

|

Other characteristic |

|

|

Throughout frying remove a micron degree contamination. |

|

Uses |

|

・Fryer for food processing

・Others for food processing such as filtering of dregs or impurities contained in water, seasoning condiment etc. |

|

Filtering process |

|

| A filter paper is rolled up in a form of a roll and is housed on the upper surface (1) Of the filtering machine. The filter paper is set between rolling up rollers (5),(6) and between holding rollers (7),(8) passing through tension roller (4) The oil level is adjusted with adjust bolts (10), (11) so that the liquid level in the fryer comes to be at the same height as the liquid level in the filtering room, when valve is opened.When turning a switch on the control panel ON, pump (12) rotates and applies negative pressure to the filtering room. With this pressure, the filter paper is closely adhered on the upper surface of the filtering room, and as the result, cleanly filtered oil is returned to the fryer through the pump. When much dirt sticks to the filter paper, the negative pressure increases to turn vacuum switch (13) to stop the pump, and then drive motor (9)linked with the rolling up roller rotates to roll up the soiled filter paper and to supply new filter paper. |

|

|

|

|

|

|

|

|

|

|

Atlas Techno Service CO.,LTD |

| 407-2,HIROTANI,KANDE-CHO,NISHI-KU,KOBE 651-2331 JAPAN CONTACT US |

| Copyrights © 2007’ Atlas Techno Service CO.,LTD All Rights Reserved. |

|

|